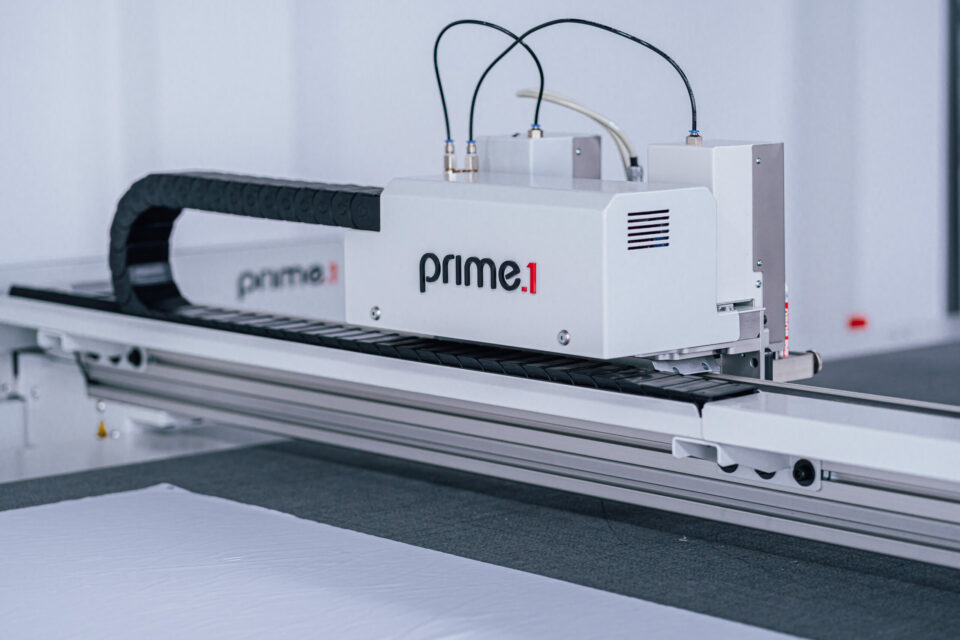

The cutter Prime.1 is an advanced machine designed for single-layer cutting of materials from rolls and coupons. It guarantees high productivity while offering flexibility in the production process. Designed with Industry 4.0 standards in mind, it enables communication with other systems in the cutting room, integrating into the Intelligent Cutting Room concept. As a single-layer cutter, it handles a wide variety of materials – from fine fabrics to denim and cevlar.

The construction of the machine ensures very low-cost technical operation of the machine and low operating costs. Sturdy construction, quick tool-changing system, long-life parts and support directly from the manufacturer – ensures high production safety and user satisfaction.

Our range also includes essential spare parts and advanced cutting room equipment, making Prime.1 the best choice for those who want automation and efficiency and low investment costs. Choose Prime.1, transform your production.