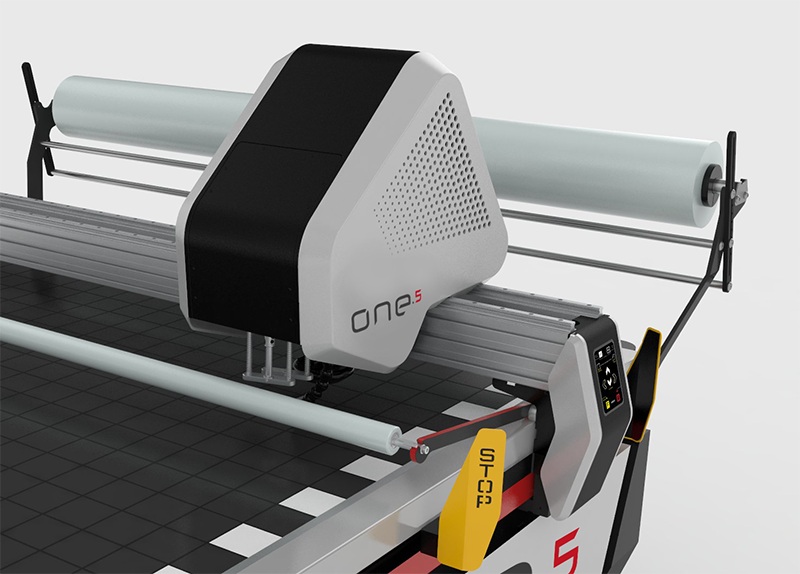

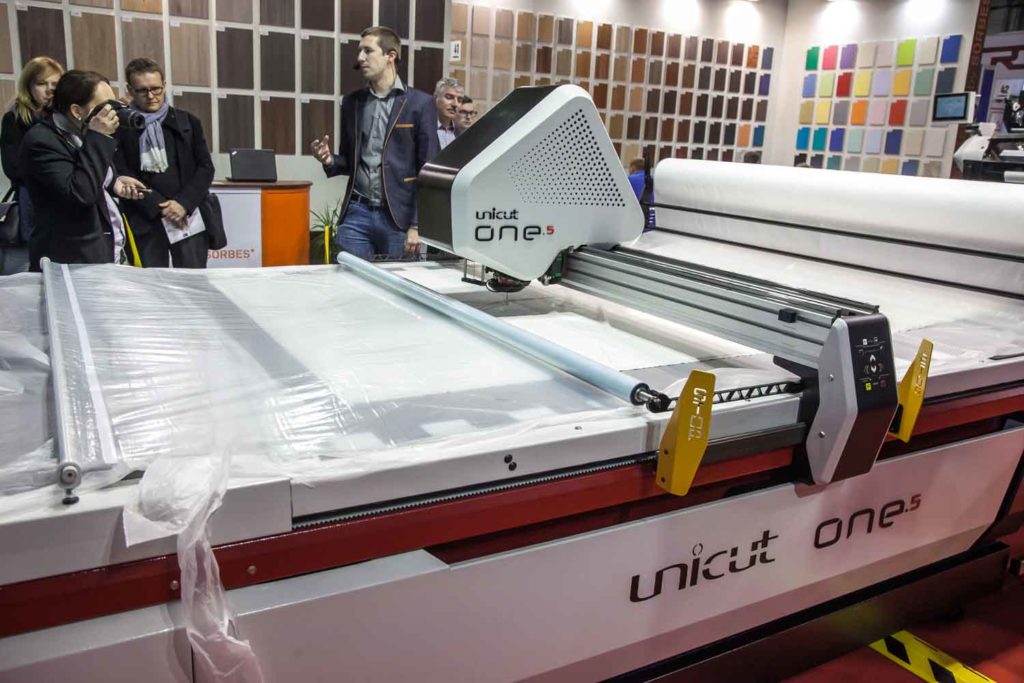

An essential piece of equipment for any cutting room, the One.5 is a caterer (cutter) that combines automation with precision. As a multilayer, low-volume and single-layer caterer, it handles a wide variety of materials – from delicate fabrics to denim and cevlar.

The machine’s construction ensures very low operating costs and low user costs. Stable design, fast rotation and brush cleaning system, long-lasting parts life, and direct support from the manufacturer ensure high production safety and user satisfaction.

Our offer also includes essential spare parts and advanced cutting room equipment, making One.5 the best choice for those seeking automation, efficiency, and low investment costs. Choose One.5, transform your production.